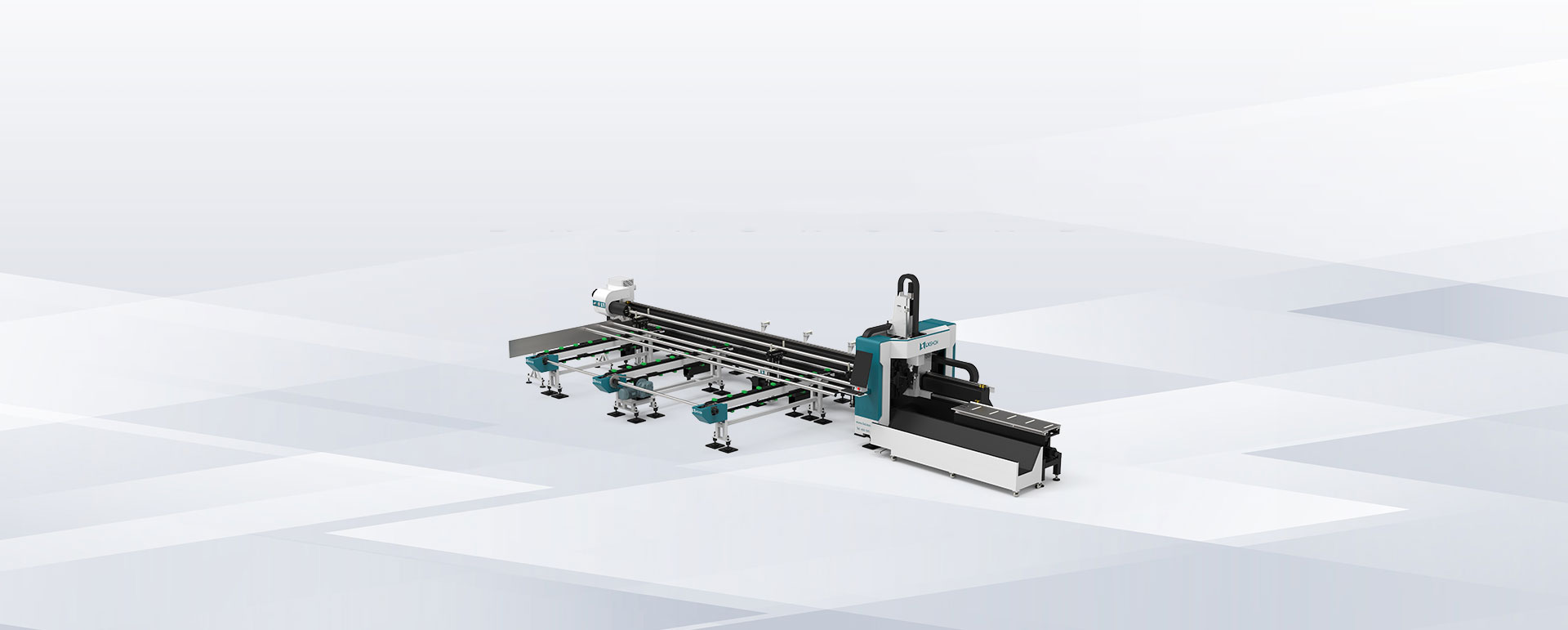

Umbhede Olenga Eceleni Ohlanganisiwe

Umbhede usebenzisa isakhiwo esilenga eceleni kanye nombhede ohlanganisiwe onengxenye eyodwa, ovalwe ukuze kuqedwe ukucindezeleka kwangaphakathi. Ngemva komshini onzima, ukuguga kokudlidliza kwenziwa ngaphambi kokuqeda umshini, ngaleyo ndlela kuthuthukisa kakhulu ukuqina nokuzinza kwethuluzi lomshini futhi kuqinisekiswe ukunemba kwethuluzi lomshini. I-AC servo motor drive ilawulwa uhlelo lokulawula izinombolo, futhi i-chuck iqaphela ukunyakaza okuphindaphindayo ohlangothini lwe-Y ngemuva kokushayela kwemoto, iqaphela ukunyakaza okusheshayo nokunyakaza kokudla. Kokubili i-Y-axis rack kanye ne-linear guide rail zenziwe ngemikhiqizo enembile kakhulu, eqinisekisa ngempumelelo ukunemba kokudluliselwa; amaswishi omkhawulo kuzo zombili izinhlangothi zokushaya ayalawulwa, futhi kufakwa idivayisi eqinile ngesikhathi esifanayo, eqinisekisa ngempumelelo ukuphepha kokunyakaza kwethuluzi lomshini; ithuluzi lomshini lifakwe Idivayisi yokugcoba ezenzakalelayo inezela uwoyela wokugcoba ezingxenyeni ezihambayo zombhede ngezikhathi ezithile ukuqinisekisa ukuthi izingxenye ezihambayo zihamba kahle, okungathuthukisa impilo yenkonzo yama-guide rails, amagiya nama-racks.

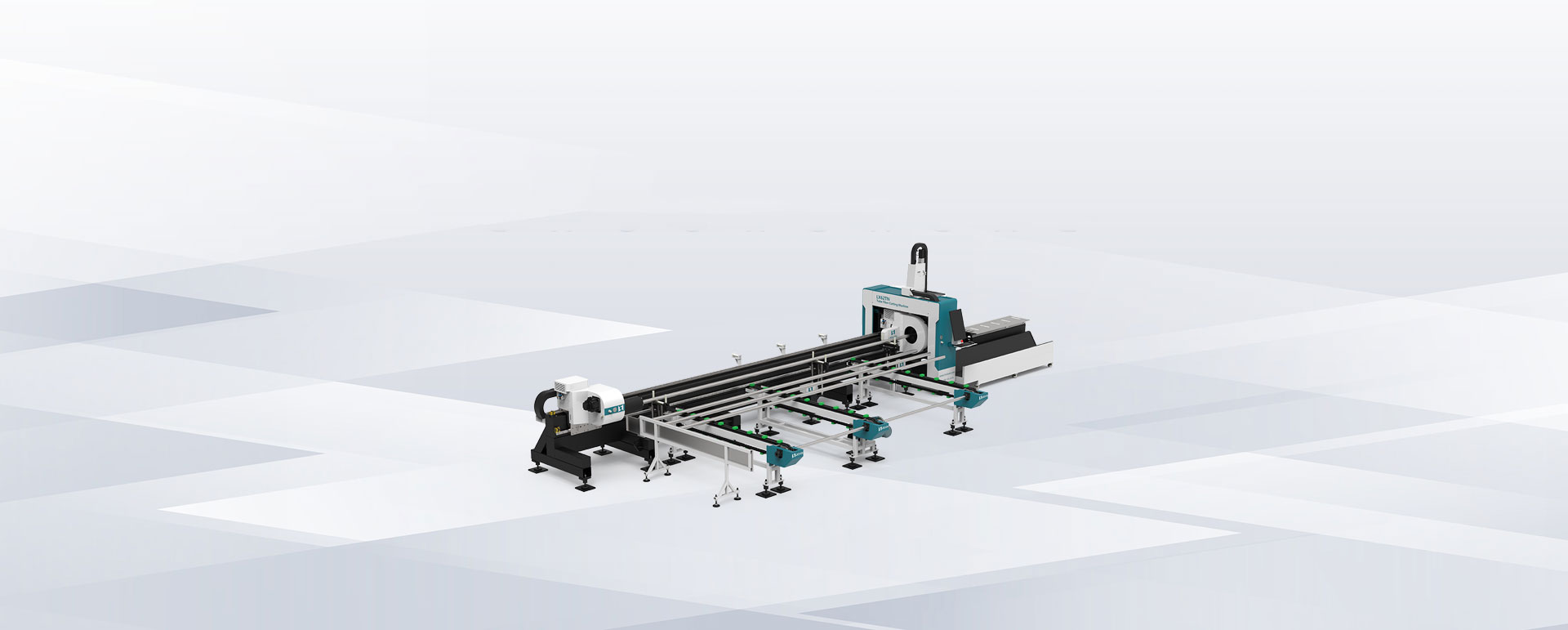

Idivayisi Yokondla Ngaphambili

Idivayisi yokondla yangaphambili ifaka ipuleti lokusekela elilawulwa yisilinda somoya, esisekela ipayipi lapho ipayipi elisikiwe lide futhi livimbele ukuthi ligobe.

Uma umsebenzi wokusika unqunywa, isilinda sokusekela esiphakanyisiwe sisekela ipuleti lokusekela ukuze lisekele ipayipi futhi silivimbele ekugobeni. Uma umsebenzi wokusika unqunywa, amasilinda okusekela aphakanyisiwe wonke ayahoxiswa, bese umsebenzi uwela epuletini elingenalutho bese ushelela endaweni yokugcina. Isenzo sesilinda silawulwa ngokuzenzakalelayo uhlelo.

Ingxenye engaphambili ihlukaniswe ngohlobo lokulandelela kanye nohlobo lokulungisa ngesandla.

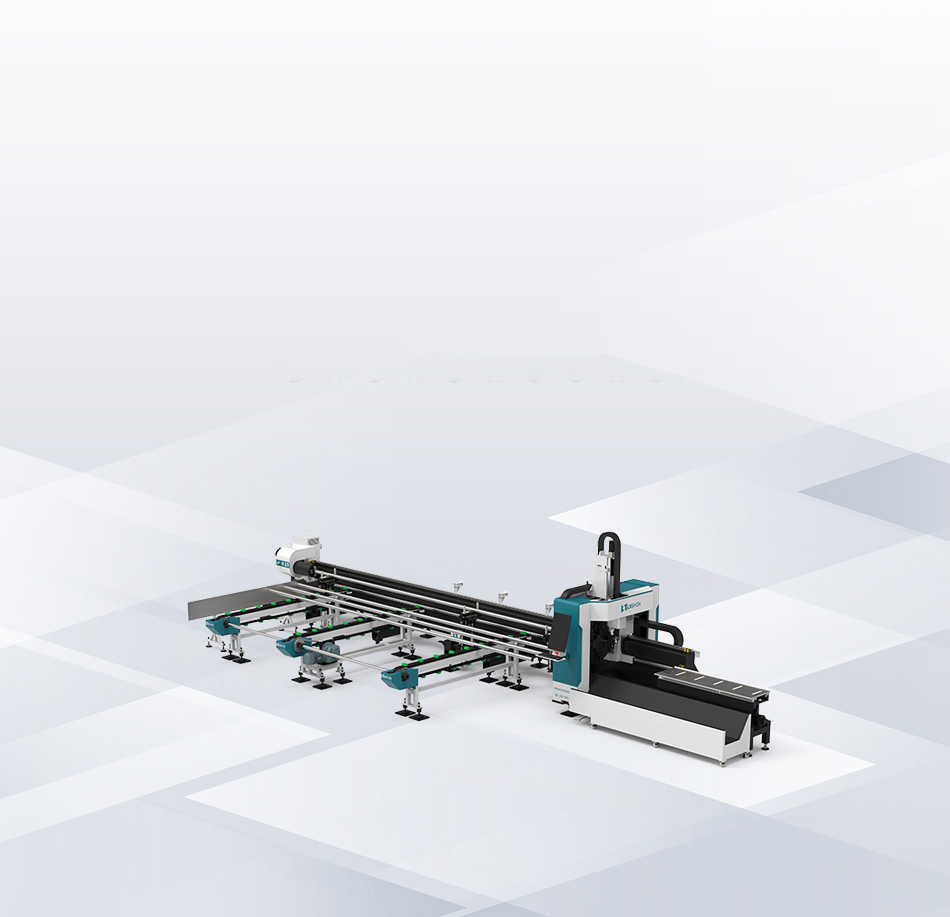

Izindlela Zokusekela

Kunezinhlobo ezimbili zezindlela zokusekela ezifakwe embhedeni, futhi kunezinhlobo ezimbili ezitholakalayo:

1. Ukusekelwa kokulandelela kulawulwa yi-servo motor ezimele ukuze ihambe phezulu naphansi, ikakhulukazi ukwenza ukwesekwa kokulandelela kokuguquguquka ngokweqile kwamapayipi amade asikiwe (amapayipi anobubanzi obuncane). Lapho i-chuck yangemuva ithuthela endaweni ehambisanayo, ukwesekwa okusizayo kungancishiswa ukuze kugwenywe.

2. Isekelo sesondo elinobubanzi obuguquguqukayo siyaphakanyiswa futhi sehliswe yi-cylinder, futhi singalungiswa ngesandla ezindaweni ezahlukene zesikali ukuze sisekele amapayipi anobukhulu obuhlukene.

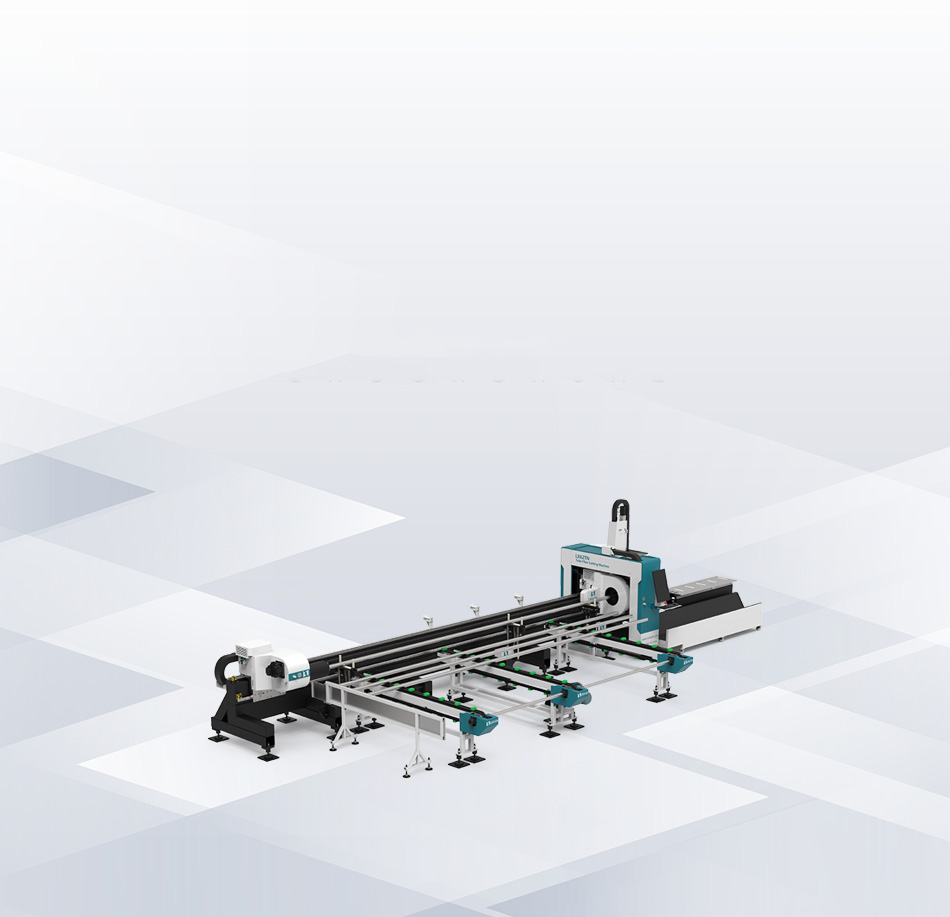

I-Chuck-Part

I-chuck ihlukaniswe ngama-chuck amabili angaphambili nangemuva asebenza ngomfutho ophakeme, womabili angahamba ngendlela ka-Y. I-chuck yangemuva inesibopho sokubopha nokondla ipayipi, kanti i-chuck yangaphambili ifakwe ekugcineni kombhede wezinto zokubopha. Ama-chuck angaphambili nangemuva aqhutshwa ngokulandelana ngama-servo motors ukuze kufezwe ukujikeleza okuhambisanayo.

Ngaphansi kokubopha okuhlangene kwama-double chucks, ukusika umsila omfushane kungabonakala, kanti umsila omfushane womlomo ungafinyelela ku-20-40mm, ngenkathi usekela ukusika umsila omfushane womsila omude.

Umshini wokusika amapayipi ochungechunge lwe-TN usebenzisa indlela yokunyakaza nokugwema ama-chuck, engenza ukusika kube ngama-chuck amabili ngaso sonke isikhathi, futhi ngeke kubangele ukuthi ipayipi libe lide kakhulu futhi lingazinzile, futhi ukunemba akwanele.

Idivayisi ye-Axis

Ugongolo oluvundlile lwedivayisi ye-X-axis lusebenzisa isakhiwo se-gantry, esihlanganiswe ngenhlanganisela yeshubhu eliyisikwele nepuleti lensimbi. Ingxenye ye-gantry inamathele embhedeni, kanti i-X-axis iqhutshwa yi-servo motor ukushayela i-rack kanye ne-pinion ukuze kufezwe ukunyakaza okuhambisanayo kwepuleti lesilayidi ohlangothini lwe-X. Enkambisweni yokunyakaza, inkinobho yomkhawulo ilawula ukushaywa ukuze inciphise isikhundla ukuqinisekisa ukuphepha kokusebenza kohlelo.

Ngesikhathi esifanayo, i-axis ye-X/Z inesivikelo sayo sezitho ukuze ivikele isakhiwo sangaphakathi futhi ifinyelele imiphumela engcono yokuvikela kanye nokususa uthuli.

Idivayisi ye-Z-axis iqaphela kakhulu ukunyakaza kokuya nokuya phansi kwekhanda le-laser.

I-Z-axis ingasetshenziswa njenge-CNC axis ukwenza ukunyakaza kwayo kokuxhunyaniswa, futhi ngesikhathi esifanayo, ingaxhunyaniswa nama-X kanye nama-Y axes, futhi ingashintshwa ibe yisilawuli sokulandelela ukuze ihlangabezane nezidingo zezimo ezahlukene.

Idivayisi ye-Axis

Ugongolo oluvundlile lwedivayisi ye-X-axis lusebenzisa isakhiwo se-gantry, esihlanganiswe ngenhlanganisela yeshubhu eliyisikwele nepuleti lensimbi. Ingxenye ye-gantry inamathele embhedeni, kanti i-X-axis iqhutshwa yi-servo motor ukushayela i-rack kanye ne-pinion ukuze kufezwe ukunyakaza okuhambisanayo kwepuleti lesilayidi ohlangothini lwe-X. Enkambisweni yokunyakaza, inkinobho yomkhawulo ilawula ukushaywa ukuze inciphise isikhundla ukuqinisekisa ukuphepha kokusebenza kohlelo.

Ngesikhathi esifanayo, i-axis ye-X/Z inesivikelo sayo sezitho ukuze ivikele isakhiwo sangaphakathi futhi ifinyelele imiphumela engcono yokuvikela kanye nokususa uthuli.

Idivayisi ye-Z-axis iqaphela kakhulu ukunyakaza kokuya nokuya phansi kwekhanda le-laser.

I-Z-axis ingasetshenziswa njenge-CNC axis ukwenza ukunyakaza kwayo kokuxhunyaniswa, futhi ngesikhathi esifanayo, ingaxhunyaniswa nama-X kanye nama-Y axes, futhi ingashintshwa ibe yisilawuli sokulandelela ukuze ihlangabezane nezidingo zezimo ezahlukene.

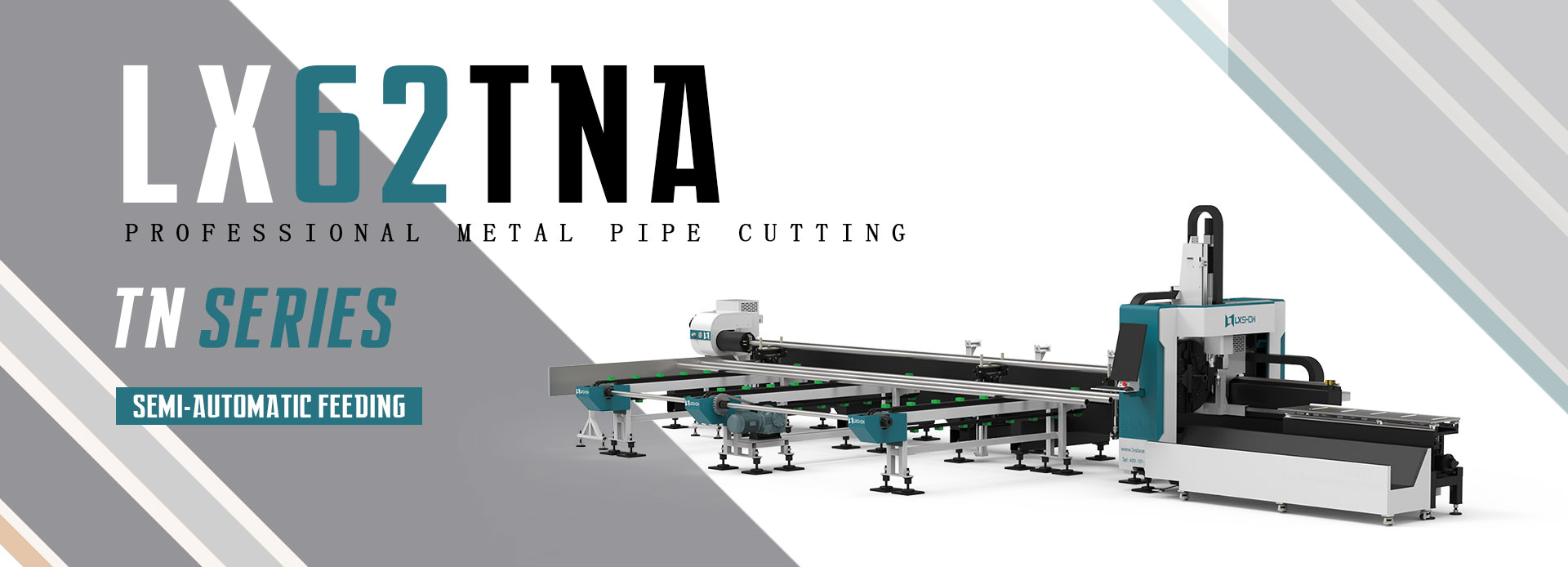

Umshini Wepayipi Lensimbi Wokusika I-Laser Ye-LX62TN Wensimbi Yensimbi Engagqwali Isicelo Sensimbi Yekhabhoni Yensimbi

Izinto Zokusebenza:

Umshini Wokusika Insimbi we-Fiber Laser ulungele ukusika insimbi njenge-Stainless Steel Tube, i-Mild Steel Tube, i-Carbon Steel Tube, i-Alloy Steel Tube, i-Spring steel Tube, i-Iron Pipe, i-Galvanized Steel Tube, i-Aluminium Pipe, i-Copper Tube, i-Brass Tube, i-Bronze Pipe, i-Titanium Pipe, i-Metal Tube, i-Metal Pipe, njll.

Izimboni Zokusebenza:

Imishini Yokusika I-Fiber Laser isetshenziswa kabanzi ekukhiqizeni i-Billboard, Ukukhangisa, Izimpawu, Izimpawu, Izinhlamvu Zensimbi, Izinhlamvu ze-LED, Izimpahla Zasekhishini, Izincwadi Zokukhangisa, Ukucubungula Insimbi Yeshubhu, Izingxenye Nezingxenye Zensimbi, Izinsimbi Zensimbi, I-Chassis, Ama-Racks & Amakhabethe Ukucubungula, Imisebenzi Yezandla Yensimbi, Izinto Zobuciko Zensimbi, Ukusika Amaphaneli E-elevator, Ihadiwe, izingxenye zezimoto, Uhlaka Lweglasi, Izingxenye Ze-elekthronikhi, Ama-Nameplate, njll.