Ukuhlukaniswa kwe-blade

H13: ikakhulukazi insimbi engagqwali

I-9CrSi: ikakhulukazi insimbi yekhabhoni, ishidi le-galvanized

Impilo yesevisi: iminyaka emi-2

I-blade iyingxenye engasetshenziswa. Ngemva kokuqinisekisa izinto, kunconywa ukuthi uthenge isethi eyengeziwe yama-blade asele.

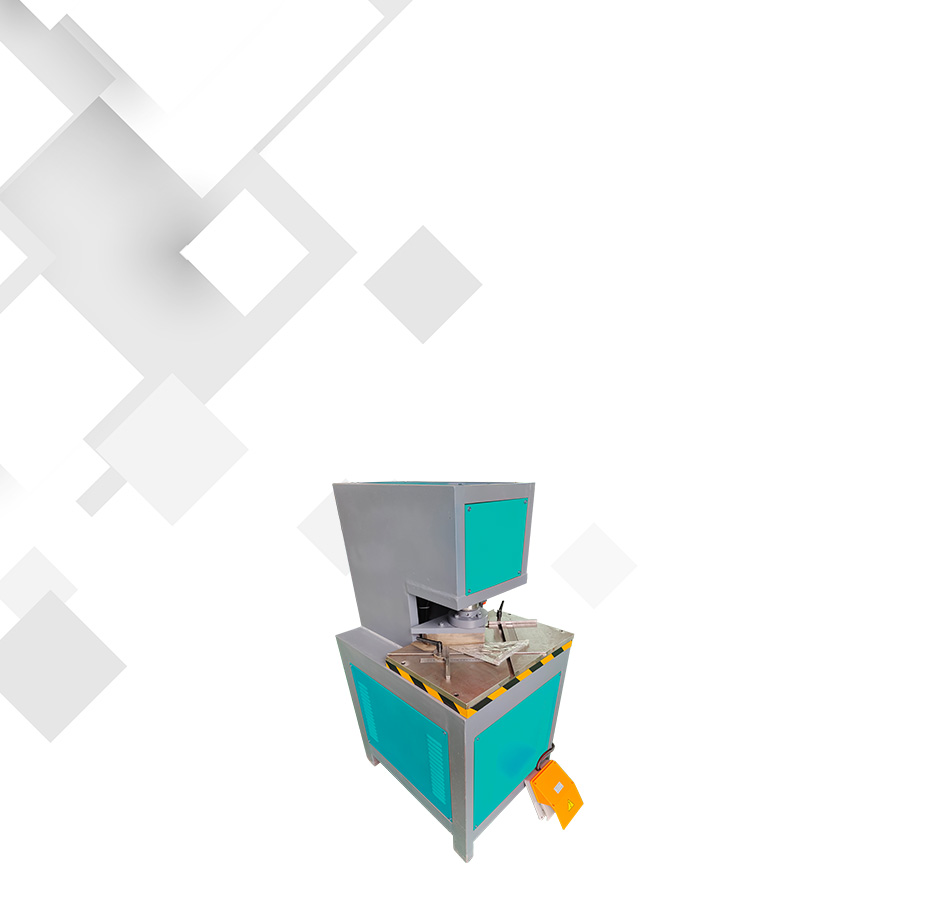

Isilinda samafutha

Ukubeka Indawo

Injini

Ukushintsha unyawo

Iphaneli yokulawula

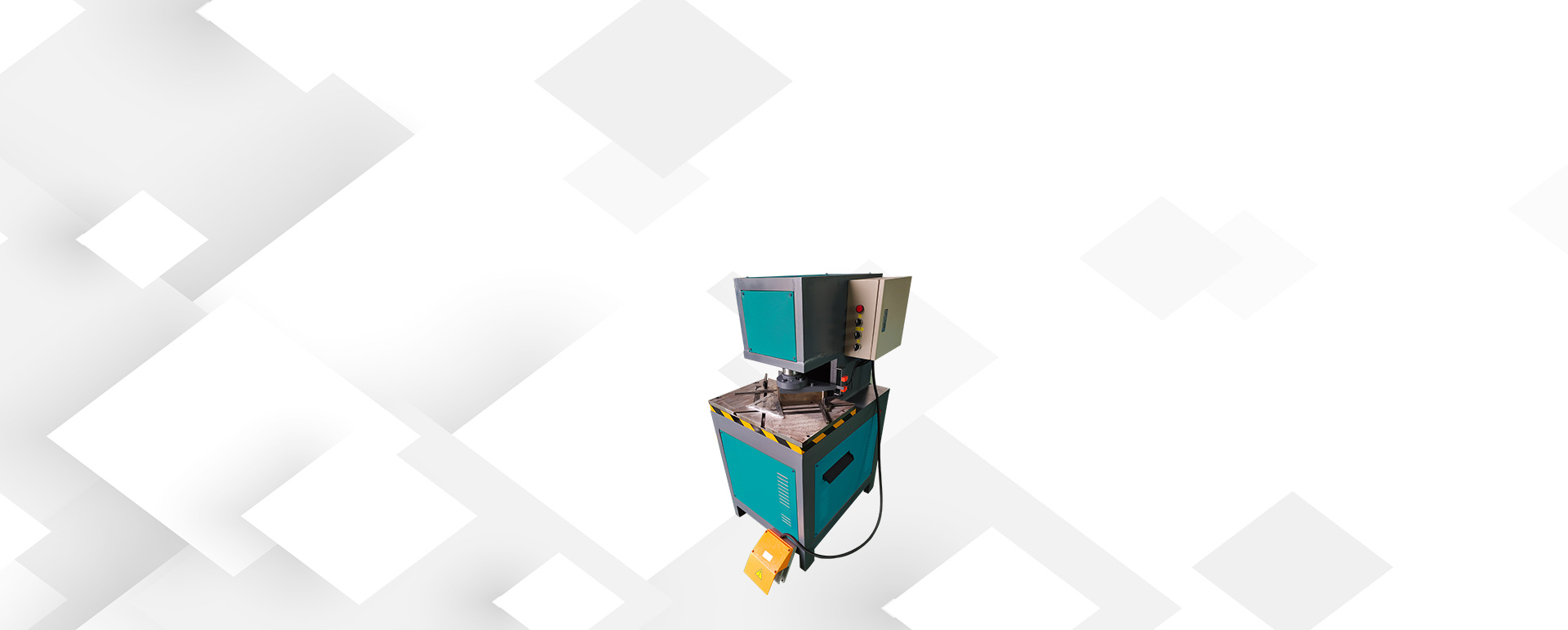

Isimiso sokusebenza somshini wokusika amakhona

Umshini wokusika ekhoneni uwuhlobo lwemishini yokusika amapuleti ensimbi. Umshini wokusika ekhoneni uhlukaniswe ngohlobo olulungisekayo nohlobo olungalungiseki. Ububanzi be-engeli obulungisekayo: 40°~135°. Ungalungiswa ngokungahleliwe ngaphakathi kobubanzi be-engeli ukuze kufezwe isimo esifanele.

Isakhiwo esiyinhloko sishiselwe yipuleti lensimbi lilonke, eliqinile futhi elihlala isikhathi eside, futhi amathuluzi anikezwe ngomshini ojwayelekile kuphela angahlangabezana nezidingo zokucubungula zezitshalo zokucubungula insimbi ezijwayelekile. Akudingeki ukwenza isethi yezikhunta zokucubungula izingcezu zomsebenzi ze-engeli noma ubukhulu obuthile njengemishini evamile yokubhoboza, okunciphisa izindleko zokusebenzisa, kunciphisa inkinga yokushintshashintsha njalo nokubopha imishini evamile yokubhoboza, kuthuthukisa ukusebenza kahle komsebenzi, futhi kunciphisa amandla abasebenzi. Kunciphisa ingozi yabasebenzi, kuyilapho ukucubungula okunomsindo ophansi kudala indawo yokusebenza ethule yamafektri nabasebenzi.

Sithengisa kakhulu imishini yokusika ekhoneni engaguquki.

Okusebenzisekayo

Izinto ezisebenzayo

Insimbi yekhabhoni, insimbi engagqwali, i-aluminium, ithusi, insimbi yekhabhoni ephezulu kanye nezinye izinsimbi;

Amapuleti angewona awensimbi kumele abe yizinto ezingenazo izimpawu eziqinile, i-welding slag, i-slag inclusions, kanye ne-weld seams, futhi akufanele abe makhulu kakhulu.

Imboni Yezicelo

Umshini wokusika ekhoneni ulungele ukusika izinto zeshidi lensimbi, futhi usetshenziswa kabanzi emikhakheni eminingi efana nezimboni zokukhiqiza izimoto, imihlobiso, ama-lifti, imishini kagesi, amakhabethe kagesi ensimbi eshidi, izitsha zokupheka kanye nemikhiqizo yensimbi engagqwali.